Truck Blind Spot Mirror: Types, Benefits, and Installation

A truck blind spot mirror offers tons of benefits for truckers, especially newbies. These advanced mirrors take the protection of side-view and rearview mirrors to the next step. It provides a more comprehensive vision of the road than traditional mirrors readily available. That is why they prove to be more beneficial for trucks.

However, there’s more to know about a truck blind spot mirror than just its broader vision. One should know more about these advanced mirrors before buying one. So, let’s explore its types, benefits, and installation methods in this detailed guide!

What Is a Truck Blind Spot Mirror?

A truck blind spot mirror is an additional mirror mounted on trucks to enhance the driver’s field of vision. Unlike standard rearview mirrors, these specialized mirrors are designed to eliminate dangerous blind spots.

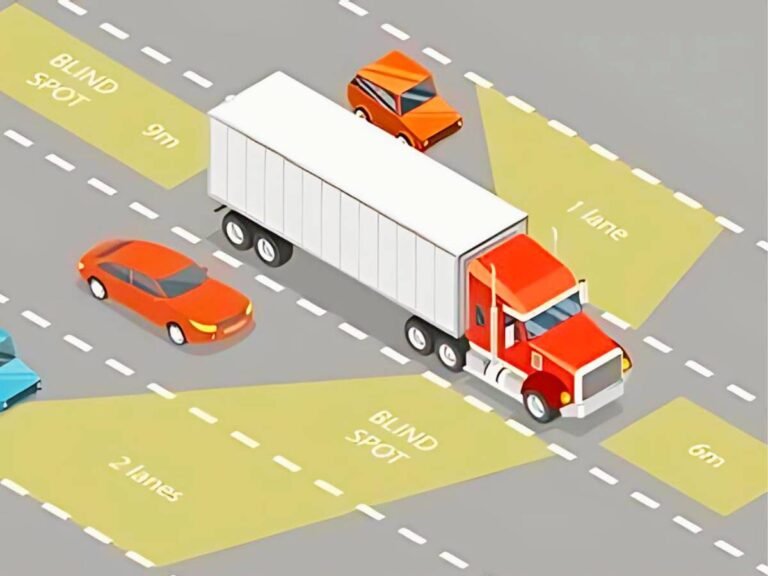

Blind spots are areas around the vehicle that the driver cannot see directly while looking through the windshield or standard mirrors. These blind spots pose significant risks, particularly for large vehicles like trucks, where visibility is more restricted.

Blind spot mirrors are crucial for truck drivers as they significantly reduce the risk of accidents. By providing a broader view of the areas alongside and behind the truck, these mirrors help drivers detect other vehicles, pedestrians, and obstacles that would otherwise be hidden. The enhanced visibility ensures safer lane changes, turns, and overall maneuvering, making the roads safer for everyone.

Types Of Truck Blind Spot Mirror

Here are the three primary types of blind spot mirrors for trucks:

Convex Mirrors

Convex mirrors are curved mirrors that provide a wider field of view than flat mirrors. The curvature causes the reflected image to be smaller, allowing drivers to see a larger area around their vehicle. This increased visibility is crucial for spotting vehicles, pedestrians, and other obstacles that may be in the truck’s blind spots.

The curved surface provides a broader view, making it easier to detect objects that are not visible in standard mirrors. By reducing blind spots, convex mirrors help prevent accidents during lane changes, merging, and reversing. These mirrors are relatively inexpensive and easy to install, making them an affordable safety upgrade for trucks.

Convex mirrors are commonly mounted on the side mirrors of trucks. They are often used as supplemental mirrors alongside the primary side mirrors to provide an extended field of view. Truck drivers rely on convex mirrors for:

- Lane Changes

- Merging

- Reversing

Fresnel Lenses

Fresnel lenses are thin, flat lenses that can be applied to the windows of trucks. They are designed to bend light, giving drivers a clear view of the truck’s surroundings, particularly the area close to the passenger side.

These lenses provide a clear view of the blind spot area on the passenger side. That is often difficult to see with standard mirrors. By improving visibility in critical blind spots, fresnel lenses help prevent side collisions and accidents during tight maneuvers. Fresnel lenses are simple to install and can be applied directly to the window glass.

While convex mirrors are mounted externally and provide a broader view by reflecting images, fresnel lenses are applied directly to the truck’s windows. Plus, they work by bending light to enhance visibility.

Convex mirrors offer a wide-angle view that covers a larger area, whereas Fresnel lenses focus on improving visibility in specific close-range blind spots.

Heated Mirrors

Heated blind spot mirrors are equipped with heating elements that prevent fogging and ice buildup on the mirror surface. These mirrors ensure that drivers have a clear view regardless of weather conditions.

The heating elements keep the mirror surface free from condensation and ice, ensuring clear visibility even in cold and wet conditions. By maintaining a clear view in adverse weather, heated mirrors reduce the risk of accidents caused by obscured vision. These mirrors are designed to withstand harsh weather conditions, providing long-lasting performance.

Heated blind spot mirrors are particularly beneficial during winter and rainy seasons. In cold weather, ice and frost can quickly form on mirror surfaces, obstructing the driver’s view. Heated mirrors prevent this by warming the mirror surface, melting ice, and preventing condensation. During rainy weather, heated mirrors help evaporate moisture, ensuring a clear view despite the rain.

Benefits of Truck Blind Spot Mirror

Now, let’s look at the benefits of a truck blind spot mirror:

1. Reduction in Accidents

One of the primary benefits of using truck blind spot mirrors is the significant reduction in accidents. Blind spots are notorious for causing collisions, especially during lane changes and merging. They help drivers detect vehicles, pedestrians, and obstacles that might otherwise go unseen. This enhanced awareness greatly reduces the likelihood of accidents, making roads safer for truck drivers and other road users.

2. Better Navigation in Tight Spaces

Navigating a large truck through tight spaces can be challenging, especially in urban environments or crowded loading docks. Truck mirrors for blind spots aid drivers in maneuvering their vehicles more accurately and safely. The expanded field of view helps drivers see obstacles that are close to the truck. That allows for precise navigation and reduces the risk of collisions with other vehicles, structures, or pedestrians.

3. Assistance in Lane Changes

Lane changes are one of the most common situations where blind spots can lead to accidents. Truck mirrors for blind spots provide the additional visibility needed to check for other vehicles in adjacent lanes. It helps drivers make safer lane changes by ensuring that the lane is clear before moving over. By reducing the blind spots, these mirrors play a vital role in preventing side collisions and enhancing overall road safety.

4. Long-Term Savings on Repairs and Insurance

In addition to preventing immediate damage, blind spot mirrors for trucks contribute to long-term savings. Fewer accidents mean fewer repair bills and a better safety record. That can lead to lower insurance premiums over time. Insurance companies often offer discounts to drivers and fleets with advanced safety equipment, including blind spot mirrors.

Installation Of a Truck Blind Spot Mirror

Before moving to installation, consider keeping the essential equipment at your side. Here’s what you will need:

- Screwdriver Set

- Wrench Set

- Drill and Drill Bits

- Measuring Tape

- Marker or Pencil

- Mounting Brackets

- Cleaning Cloth

- Adhesive or Sealant

Then, also use safety gear including safety glasses, gloves, and product manual. Have anything ready? Follow the installation process:

- Use a cleaning cloth to thoroughly clean the area where the blind spot mirrors will be mounted. Removing dirt and grease ensures better adhesion and a secure fit.

- Use the measuring tape to determine the optimal position for the blind spot mirrors. Typically, these are mounted on the lower outer corner of the existing side mirrors.

- Use a marker or pencil to mark the exact spots where the mounting brackets will be attached.

- Then, using the screwdriver or drill, attach the mounting brackets to the marked positions. If drilling is required, ensure you use the correct drill bit size to avoid damaging the mirror housing.

- Tighten the screws or bolts to ensure the brackets are firmly attached. Double-check that they are secure before proceeding.

- Place the blind spot mirrors onto the mounting brackets. Adjust them to ensure they are properly aligned and provide the best possible view.

- Tighten any screws or clamps to hold the mirrors in place. Make sure they are firmly attached and won’t move while driving.

- Sit in the driver’s seat and adjust the mirrors as needed to ensure they cover the blind spots effectively. The mirrors should provide a clear view of the side and rear of the truck.

- Gently tap the mirrors to ensure they are securely mounted and do not wobble or shift.

Conclusion

A truck blind spot is an indispensable safety feature for any truck driver or fleet operator. It provides enhanced visibility, reduces blind spots, and prevents accidents. These mirrors play a crucial role in ensuring safer roads for everyone. Whether you opt for convex mirrors, Fresnel lenses, or heated blind spot mirrors, each type offers unique benefits tailored to different driving conditions and needs.

Installing a truck mirror blind spot is a straightforward process that can be done with basic tools and careful attention to alignment. The investment in these mirrors not only improves safety but also offers long-term cost savings!