Why Blind Spot Monitors are Essential for Trucks?

In today’s world of transportation, ensuring safety on the road is paramount. That is especially true for large commercial vehicles like trucks. One of the critical components in enhancing truck safety is the implementation of blind spot monitors (BSMs). It’s important to understand what the Blind Spot Monitoring system offers for the drivers. These systems act as an extra set of eyes for truck drivers, mitigating the risks associated with blind spots.

Blind Spots in Trucks – All You Need to Know

Blind spots in trucks refer to areas around the vehicle that are not directly visible to the driver, even with the use of mirrors. Due to their large size and unique design, trucks have substantial blind spots. That’s especially true on the sides and rear of the vehicle. These blind spots create zones where other vehicles, pedestrians, or obstacles may go unnoticed by the truck driver, increasing the risk of accidents.

For truck drivers, navigating these blind spots presents significant challenges. Not being able to see vehicles or objects in these areas can lead to accidents. Generally, that happens during lane changes, merging, or when making turns. The inability to detect nearby vehicles or pedestrians can result in collisions, injuries, or even fatalities. Additionally, blind spots can make it difficult for truck drivers to maneuver safely in congested traffic or tight spaces, maximizing the risk of accidents.

Truck Blind Spot Accidents

According to studies and reports from transportation safety agencies, blind spots are a contributing factor in a significant number of accidents involving trucks. Statistics reveal that a considerable percentage of truck-related accidents occur due to issues related to visibility, including blind spot-related incidents. These accidents often result in severe consequences, highlighting the urgent need for effective solutions to mitigate the risks associated with blind spots in trucks.

How Blind Spot Monitors Can Help Trucks

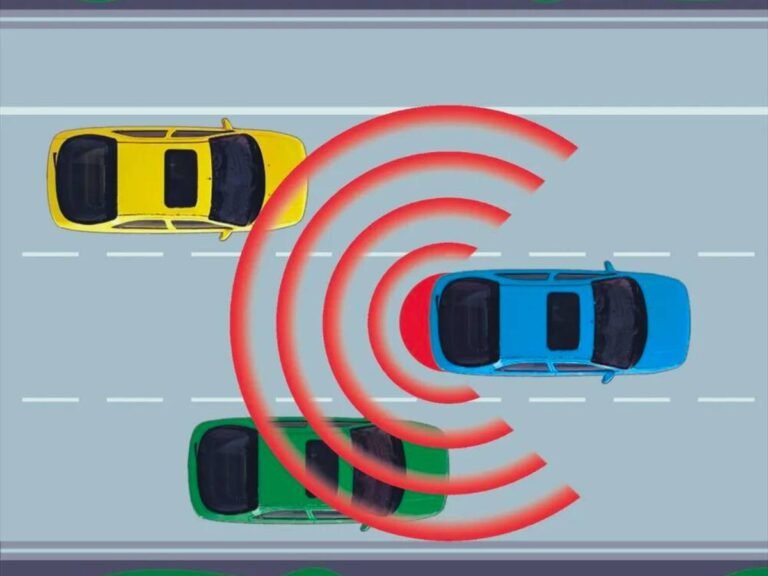

Blind spot monitors (BSMs) are advanced safety systems designed to enhance visibility for truck drivers. Ultimately, they help mitigate the risks associated with blind spots. These monitors typically utilize a combination of sensors, cameras, and radar technology to detect objects or vehicles. When a vehicle or obstacle is detected, the system alerts the driver through blind spot warning lights, and auditory signals, providing warnings to take action.

Generally, blind spot monitors are available for every vehicle. Besides trucks, that includes cars, motorcycles, vans, emergency vehicles, and buses. However, a truck’s danger zones are significantly more threatening. Thus, BSM is more of a necessity for trucks, especially in today’s crowded highways.

Benefits Of Blind Spot Monitors

The implementation of blind spot monitors offers a multitude of benefits for truck drivers. Firstly, BSMs significantly reduce the likelihood of accidents caused by blind spot-related incidents. By providing real-time alerts, these systems make certain situations safer. That includes lane changes, merges, and turns, thus preventing collisions and potentially saving lives.

Moreover, blind spot monitors enhance overall situational awareness for truck drivers. That is by empowering them to make informed decisions and navigate challenging driving conditions with greater confidence and ease.

Countless accidents have been averted thanks to the proactive intervention of blind-spot monitors.BSMs have proven instrumental in enhancing truck safety on the road. Real-world examples abound with stories of near-misses transformed into safe outcomes.

The Costs Involved in Installed Blind Spot Monitors in Trucks

Investing in blind spot monitors (BSMs) for trucks involves initial costs for equipment purchase and installation. The cost varies depending on the type of BSM technology chosen, the number of trucks equipped, and installation complexity.

However, advancements in technology have led to more affordable options, making BSMs increasingly accessible to trucking companies of all sizes.

While the upfront blind spot monitor price with installation and maintenance may seem significant, the long-term benefits far outweigh the initial investment. BSM reduces the risk of accidents and associated costs such as property damage, medical expenses, legal fees, and insurance premiums. All of these issues contribute to substantial savings over time. Moreover, the enhanced safety provided by BSMs can help preserve the reputation of trucking companies and attract more business opportunities.

With proper implementation and utilization, BSMs can yield a high ROI. That is by reducing accident-related expenses, minimizing downtime, and improving overall operational efficiency. Additionally, the intangible benefits of enhanced safety contribute to the ROI equation with a positive work environment and boost company morale.

Key Factors to Consider When Buying a Blind Spot Monitor for Trucks

Here are some crucial aspects to keep in mind when buying a blind spot monitor for trucks:

Accuracy and Reliability

Look for a BSM system known for its accuracy in detecting objects and vehicles in blind spots. Reliability is paramount, especially in challenging weather conditions or varying environments. Also, consider going for a sensor that doesn’t get affected by the environment’s lighting. Otherwise, it might not work efficiently during the night in areas without proper lighting.

Type of Technology

Evaluate different types of BSM technologies available, such as radar-based, camera-based, or ultrasonic-based systems. Each technology has its advantages and limitations, so choose the one that best suits your operational requirements and budget.

Coverage Area

Assess the coverage area of the blind spot monitor to ensure it effectively detects objects in all critical blind spots around your truck. Opt for a system with comprehensive coverage to maximize safety on the road.

Installation and Maintenance

Evaluate the ease of installation and ongoing maintenance requirements of the BSM system. Choose a solution that can be installed efficiently without extensive downtime and requires minimal maintenance to keep it operating optimally.

Alert System

Consider the type of alerts provided by the BSM, whether visual, auditory, or both. Look for customizable alert settings that allow drivers to adjust alerts based on their preferences and driving conditions.

FAQs

what is the no zone in driving?

The no zone in driving refers to areas around large vehicles, especially trucks and buses, where the driver has limited or zero visibility. These zones are incredibly dangerous because other drivers can be completely hidden from the truck driver’s view, significantly increasing the risk of accidents.

Conclusion

Blind spot monitors serve as vigilant guardians, providing truck drivers with invaluable assistance. That is especially true in detecting potential hazards and mitigating risks associated with limited visibility. Through advanced sensor technologies and real-time alerts, BSMs empower drivers to make safer decisions, navigate challenging environments, and protect lives—both their own and those of others sharing the road.